Toyo Stainless Polish Industry, which owns the MAKO brand, offers high-quality mirror panels made of stainless steel and titanium, ideal for architectures and interiors. These panels combine beautiful lusters with durability, delivering exceptional performance across various applications.

Not only 2D designing panels but also 3D designing panels and a combination of both panels are possible with our customizable and characteristic mirror panels.

contents

Features of Mirror Panels

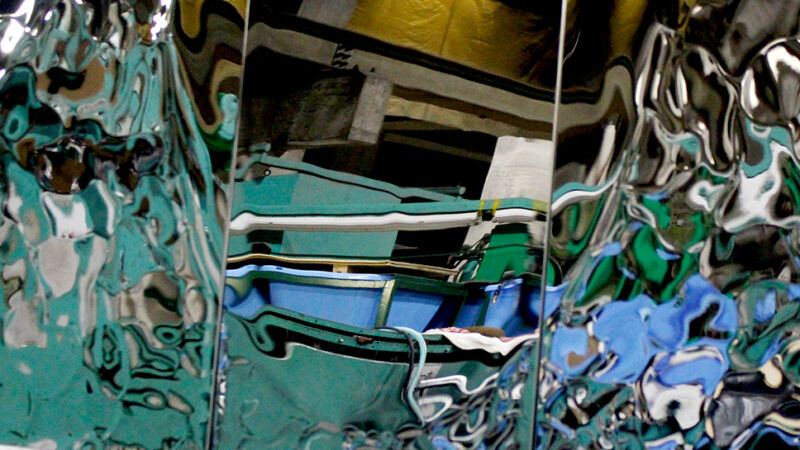

- High Reflectivity

The mirror finish makes a space look more spacious and brighter. - Durability

Excellent corrosion resistance maintains beauty for a long time. Especially stainless steel is resistant to rust and easy to maintain. - Versatility

Suitable for walls, ceilings, decorative panels, and more. It performs exceptionally well in public spaces such as entrance halls and lobbies.

Examples of the Application of Mirror Panels

Architectures

- Entrances

Create a luxurious impression and leaves a strong impact on visitors. - Elevators

Transform the interior atmosphere with its application. - Lobby wall decorations

Create a sense of expansion and brightens the space visually.

Interiors

- Commercial facilities

Used for the interiors of shopping malls and restaurants, providing a modern and sophisticated atmosphere. - Hotels

Applied in guest rooms and common areas, balancing luxury and comfort. - Residences

Suitable for various locations in homes, such as kitchens and bathrooms.

Benefits of Mirror Panels

- Easy Maintenance

Mirror-finished stainless steel is resistant to dirt, easy to clean, and maintains a beautiful appearance. - Environmental friendliness

Stainless steel is easy to recycle and is noted as a sustainable building material.

Specifications and Optional Finishes of Mirror Panels

- Size and thickness

Customizable to desired sizes and thicknesses to meet specific project requirements. - Optional finishes

In addition to the standard mirror finish, we offer various finish options such as satin and hairline.

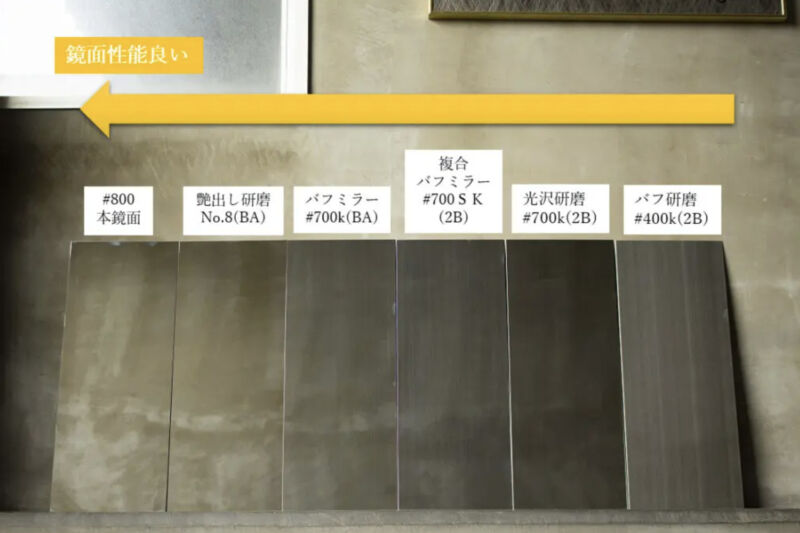

Types of Stainless Steel Mirrors and Difference in Appearance

Full Mirror Polish (#800)

Characteristics: Finished with #800 initial grinding stone, extremely beautiful mirror finish.

Applications: High-grade signages, building materials, fixtures.

Disadvantages: High cost, long lead time.

No.8 Polish (BA)

Characteristics: Commonly used in stainless steel mirrors, hand mirrors, products, etc.

Disadvantages: Limited plate thickness, a change in gloss after welding.

Buff Mirror #700K (BA)

Characteristics: Suitable for building materials and processing uses, featuring thin longitudinal streaks.

Disadvantages: Not suitable for luxury applications.

Composite Buff Mirror #700SK

Characteristics: Suitable for thick and/or wide plates, equivalent to #700K grade.

Disadvantages: High cost, long lead time.

Glossy Polish #700K

Characteristics: Enhanced gloss version of standard #400 buff polish.

Applications: Fixtures, hygiene-focused tanks, etc.

Buff Polish #400

Characteristics: Most versatile, widely used for industrial and food equipment.

Disadvantages: Causes diffuse reflection under sunlight or indoor light.

Conclusion

Toyo Stainless Polish Industry’s mirror-finished stainless steel panels are ideal as building and interior materials, combining beauty and functionality.

With various applications and optional finishes, they can cater to all project needs.

We look forward to your inquiries.