contents

Improving Corrosion Resistance with MaCoatGC for Aluminum

Aluminum is prone to corrosion compared to stainless steel and titanium, so it is usually coated with an anodized oxide film called anodizing for protection.

Various decorations can be achieved, from simple white anodizing to colored anodizing. In recent years, glossy anodizing has also become possible and is used in various spaces. In addition to anodizing, surface decoration can also be achieved through painting, clear coating, or applying printed sheets, allowing for unique designs distinct from aluminum’s natural appearance.

However, with anodizing or painting, the intrinsic appearance of aluminum tends to fade away, making it challenging to capture the essence of aluminum’s natural, bright, and beautiful shine. To address this, we conducted tests to enhance corrosion resistance using our MaCoatGC.

In conclusion, after 1000 hours of salt spray testing, it may not match the corrosion resistance of titanium or stainless steel, but it provides corrosion resistance comparable to standard untreated aluminum or anodized products.

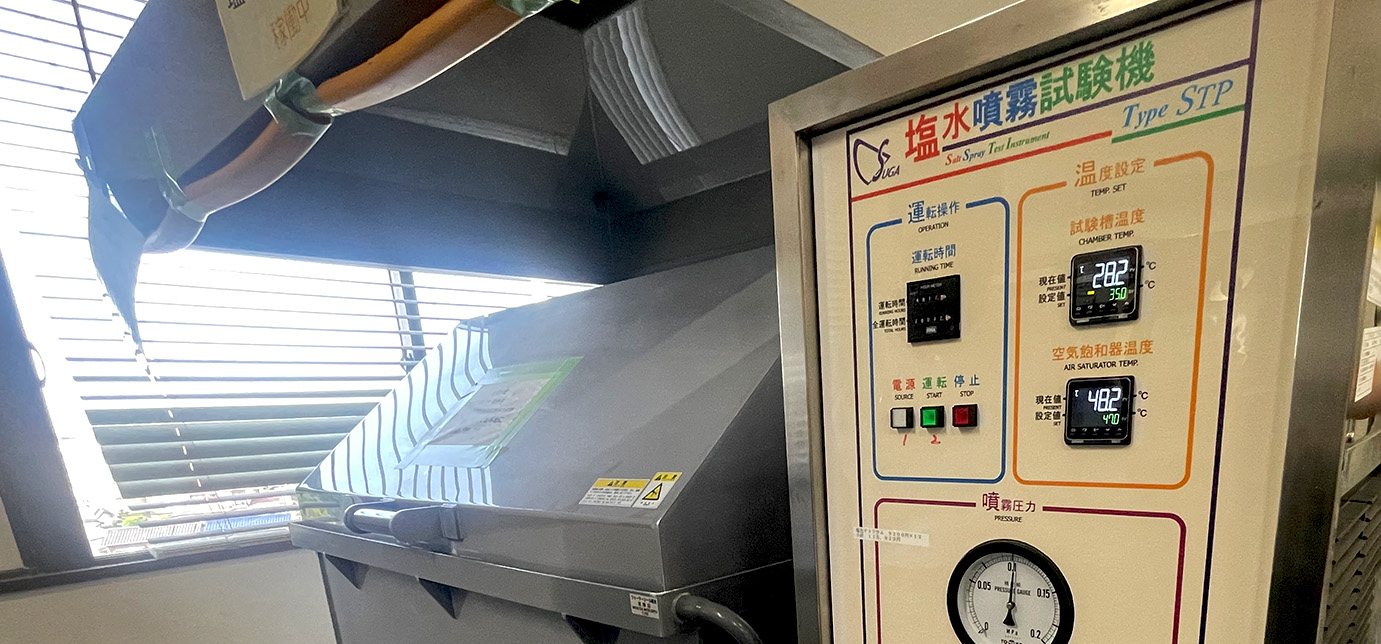

About Salt Spray Testing

Salt spray testing is a method for evaluating the corrosion resistance of products, components, or test pieces that have been subjected to various treatments such as metal materials, coatings, plating films, and coatings. This test promotes corrosion by continuously spraying saltwater on the test samples to evaluate their corrosion resistance. This test is conducted to confirm the corrosion resistance of products.

Main types of salt spray testing:

1) Neutral Salt Spray Test: This test involves spraying a common saltwater solution on the test subject and observing its progress after rinsing. A 5% sodium chloride solution is typically used as the test solution.

2) CASS Test (Copper-Accelerated Acetic Acid Salt Spray Test): This test involves spraying a water solution consisting of neutral salt spray, acetic acid, and copper chloride, creating a more corrosive environment than neutral salt spray testing.

The purpose of salt spray testing is to evaluate the “corrosion resistance” of products, which refers to their ability to withstand rust and corrosion. This test is particularly crucial for products that have potential implications for safety, such as parts used in automobiles or medical devices.

Application of Salt Spray Testing

Salt spray testing is often chosen as an accelerated test for atmospheric corrosion. However, it does not cover all environmental factors and conditions, making it more of a comparative evaluation method. It is commonly used for comparing conventional and developmental products or for quality control.

Duration of Salt Spray Testing

Salt spray testing is not an accelerated test, so the duration can vary depending on the region and environmental conditions. However, it can provide a reasonable judgment criterion by comparing the damage level with the current products.

Before Starting Salt Spray Testing

[Caption: 4817.5 hours on the meter]

Results after 1000 Hours of Salt Spray Testing

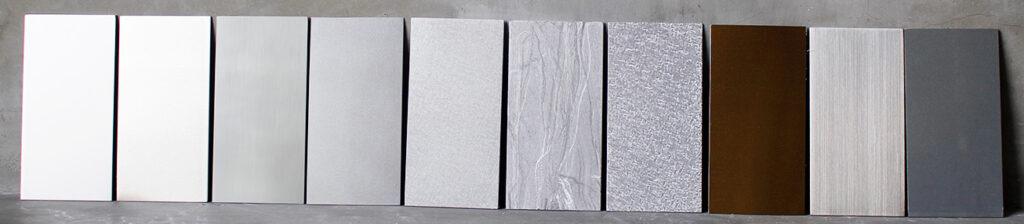

Before Salt Spray Testing

After 1000 Hours of Salt Spray Testing

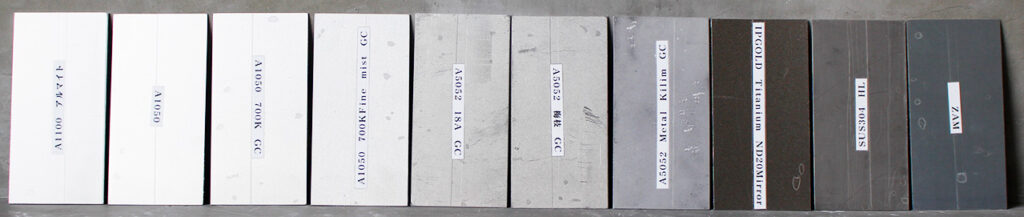

Back View

From Left:

A1100 Anodizing

A1050 Untreated Aluminum

A1050 Mirror Finish + MaCoatGC

A1050 Beads Blast + MaCoatGC

A5052 Vibration + MaCoatGC

A5052 Plum Branch + MaCoatGC

A5052 Metal Kilim + MaCoatGC

IP Gold Titanium

SUS304 Hairline

ZAM

It is evident that the MaCoatGC effect is sustained in the mirror finish, maintaining a glossy appearance. Although some rust is