Stainless steel polishing can be broadly divided into two methods: machine polishing using equipment for polishing plates, structural steel, pipes, and other materials, and manual polishing for shaping objects and small items. In particular, manual polishing is performed by skilled craftsmen, and its transmission relies heavily on intuitive and responsive techniques, making it challenging to pass on.

The subtle balance of applying the right amount of pressure, maintaining consistency, and adjusting the angle greatly influences the quality of the work.

contents

Representative Examples of Manual Polishing Equipment

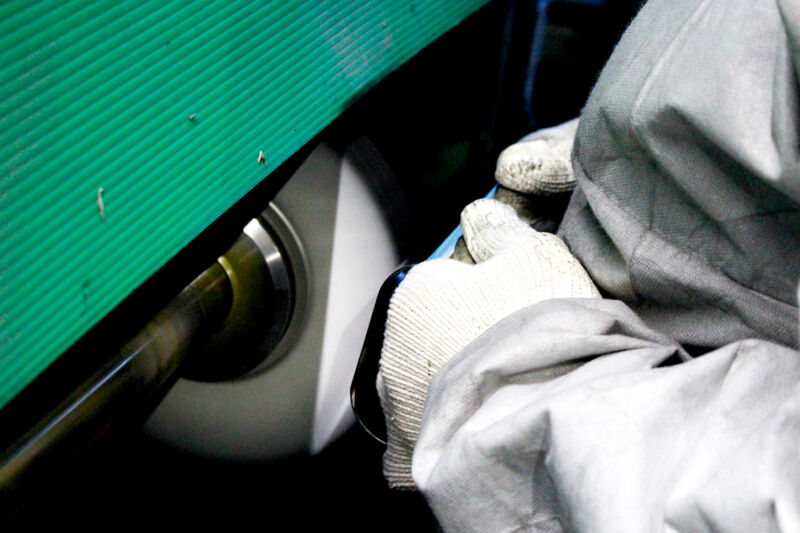

Manual polishing equipment comes in various sizes, but typically involves using a rotating axis with stacked layers of cloth resembling wheels, called buffs, as shown in the photo below. The equipment allows for precise adjustments such as continuous speed control and shaft length, enabling craftsmen to leverage their skills. Furthermore, the types of buffs and polishing compounds can be freely customized to match the object being polished.

To polish an object, it is brought into contact with the buff and polished while adjusting the applied pressure and the rotational speed of the buff. Initially, the process starts at around #400 grit and eventually progresses to achieving a mirror finish using this equipment.

Polishing Compounds Used in Manual Polishing

The choice of polishing compounds in manual polishing depends on the grade of polishing, the type of material being polished, and the type of metal. Particularly for non-ferrous metals, specific polishing compounds are required to ensure the desired quality grade. Regarding mirror polishing, the combination of polishing compound and buff is particularly crucial.

Buffs Used in Manual Polishing

Various types of buffs are used in manual polishing. Hard buffs are ideal for removing rough metal surfaces or scratches. Coarse buffs are used for repairing welded areas with grinding marks. On the other hand, achieving a fine, polished, and shining surface, such as a mirror finish, requires the use of extremely soft buffs.

Buff Used for Removing Black Scale

Stainless steel hot-rolled materials (No.1) and black scale materials made of iron are covered with a hard oxide film on their surfaces. Therefore, the first step involves removing this hard oxide film and leveling the surface finely. For this task, buffs arranged in a ring shape with sandpaper attached are used.

Polishing Machinery Used in Manual Polishing

Generally, small objects are processed using stationary buff polishing equipment. However, large tanks or structures require individuals to enter and perform polishing or polish the surfaces from the surrounding areas. Therefore, portable polishing machinery that can be held by hand is used for polishing operations.

Summary

Recently, there have been DIY polishing tutorials and videos on the internet. However, it is safer to undergo grinding and polishing training, such as using grinding grinders. It is essential to always wear protective goggles, masks, and take various safety precautions, such as preventing the scattering of particles and inhaling dust.

When polishing hollow objects like pipes, it produces loud noise. Prolonged exposure to loud noise can be harmful to the ears. Therefore, we recommend taking thorough safety measures when engaging in polishing activities.

*This product is sold by our subsidiary.

It is available for purchase online.

MaCoat GC