Metal surfaces may be coated in various ways depending on their function.

Basically, stainless steel because of its toughness, weather resistance, and durability.

By selecting the right grade of steel, called stainless steel grade, in the right place

The choice of coating is made by selecting the right grade of steel, called stainless steel grade.

However, even stainless steel is not absolutely free from rust, since the majority of its components are iron.

The key point in selecting the rope grade is to extend the period of rust spreading.

Of course, regular maintenance will prevent rust from occurring.

In this column, we will explain the case where we dare to apply coatings.

contents

Case of coating on stainless steel

When it comes to coatings on metals, there is a very wide range and subdivision.

Therefore, we would like to describe the cases of coating from the viewpoint of typical applications.

(1) Identification

(2) Design

(3) Fingerprint resistance

(4) Corrosion prevention

5)Antibacterial/antiviral

(6) Heat insulation

In this column, we will explain each of the above six scenarios in detail.

identification

This is done for identification purposes.

It is more of a painting or printing range than a coating.

Since it is a coating, spray, brush, roller application, silk printing, etc. fall under this category.

Design

Coating or coloring may be applied to stainless steel to improve design and design, utilizing its design.

Clear Coating to Utilize the Base of Stainless Steel

Color clear coating to give color tone to stainless steel by taking advantage of its bare surface.

Color stainless steel, which makes the best use of the stainless steel base material and gives it a chemical coloring.

Electrolytic coloring to blacken stainless steel by utilizing the stainless steel base

Vacuum deposition to form a tough film on stainless steel by taking advantage of its bare surface.

These are some of the examples.

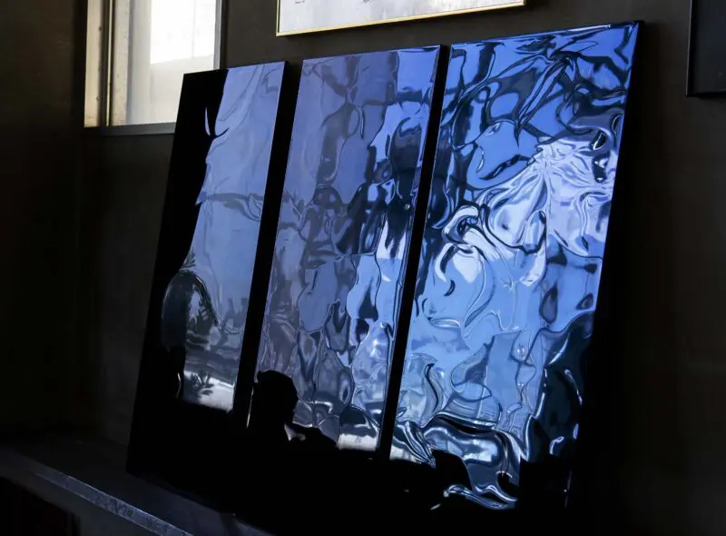

An example of interior panels made of stainless steel (Mysterious Stainless Mirror Ripples) with blue chemical coloration. It is possible to bring luster and gloss like the surface of a deep lake.

Example of interior panels made of stainless steel (Mysterious Stainless Mirror Ripples) with gold vapor deposition (ion plating).

fingerprint resistant

Fingerprints adhere to smooth surfaces of metals, including stainless steel.

In particular, fingerprints are more likely to adhere to design steel sheets of stainless steel, such as hairline and vibratory steel sheets.

Therefore, various products are available, including pre-coated steel sheets that are coated in the factory and coatings that are applied afterwards.

The fingerprint resistance effect depends on the chemicals used, but depending on the condition of the stainless steel surface, the coating may exhibit strong durability.

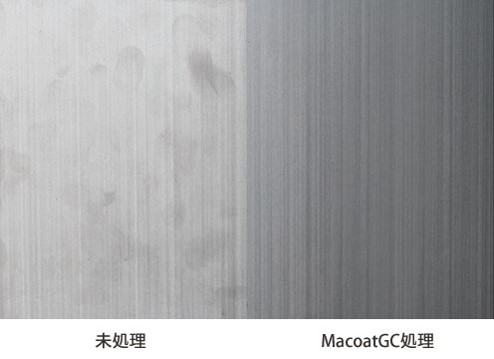

You can see the resistance to fingerprints.

Here is an article that explains the fingerprint resistance of stainless steel in detail.

By using the anti-fingerprint coating solution MaCOat-GC

It is scratch and fingerprint resistant, and dirt is repelled so that it can be easily removed by wiping with water or a neutral detergent.

For details, click here.

https://www.top-macoat.co.jp/coating/

MaCoat-GC construction video

Corrosion prevention

Although stainless steel is a rust-resistant metal, rust will occur and progress depending on the environment.

In particular, rust is frequently introduced by wind and rain, and if the surface is not cleaned or otherwise maintained on a regular basis, rust will occur.

The role of the coating is to suppress this rusting.

The following is an explanation of the actual effect based on our outdoor exposure tests.

Our company is located in Dazaifu City, Fukuoka Prefecture, adjacent to the Dazaifu Interchange on the Kyushu Expressway.

Due to the nature of Fukuoka Prefecture, PM2.5 and yellow sand fall from the continent.

Also, being on the side of an expressway, the area is exposed to Sox and Nox due to exhaust gases.

Upper part: MaCoat GC coating Lower part: No coating

Whether or not the stainless steel is polished and then coated (MaCoat_GC) with a glass coating called coating (MaCoat_GC)

After 5 years, a significant change in the rusting situation will occur.

Upper part: MaCoat GC coating Lower part: No coating

Upper part: MaCoat GC coating Lower part: No coating

Rust has formed over time on the uncoated areas.

It is important to apply a good coating to protect against rust.

Fingerprint resistant coating agent MaCoat-GC (MaCoat GC) is also effective in improving corrosion resistance.

For more information about fingerprint resistant coating agent MaCoat-GC (MaCoat-GC)

https://www.top-macoat.co.jp/coating/

MaCoat-GC application video

There are various threats such as the recent new coronavirus and O157, which has raged in the past.

Therefore, when stainless steel is used in areas where food is handled, it is often coated with an antibacterial/antiviral coating to ensure the safety of the food.

In order to ensure food safety, stainless steel surfaces are sometimes coated with antibacterial and antiviral coatings.

One point to note is that it is difficult to confirm the effectiveness of the coating at any given time, as it is dependent on the environment in which it is used.

Therefore, one option is to use stainless steel itself as a grade with antimicrobial properties.

Examples of antimicrobial stainless steel for equipment

Examples of antimicrobial stainless steel for equipment

Even antimicrobial stainless steel can be used for design expression.

Learn more about the effects of antimicrobial designing stainless steel.

Click here for product details of antimicrobial designing stainless steel.

heat insulation

When stainless steel is used in hot tanks or at low temperatures, the chamber can be jecked and

Structural thermal insulation and coating (spraying) insulation may be used to achieve this performance.

Summary of Coatings on Stainless Steel

In this article, we have introduced examples of coatings on stainless steel.

In any of these processes, it is important to first select a stainless steel grade that is suitable for the application and operating environment.

After that, it is important to select a coating that matches the performance and function.