Common stainless steel is a mixture of iron, chromium, and nickel, and is basically silver.

However, stainless steel is not only silver, it can be colored by painting or chemical coloring.

Colored stainless steel is called “colored stainless steel,” and in this column article, we will explain what kind of coloring methods are available, how the surface looks, and what the characteristics of the coloring method are.

Colored stainless steel offers a wide range of choices depending on the application. Please read the column article and feel free to contact us if you are interested.

contents

Coloring of Stainless Steel

As you all know, common stainless steel is a mixture of iron, chromium, and nickel.

In other words, the color of stainless steel is basically silver.

So, have you ever heard about colored stainless steel?

It is commonly referred to as colored stainless steel.

In this column, I will focus on the method of how to make this silver-colored stainless steel into colored stainless steel.

How to color stainless steel

The most common coloring method that immediately comes to mind is painting.

Stainless steel can be colored by painting it.

If you add a little bit of color to a thin transparent paint called clear paint, you can create colored stainless steel that makes use of the stainless steel substrate.

Painting is basically called coloring.

The next step is to control the thickness of the passive film on the surface of the stainless steel, which refracts light like a rainbow to create the color.

There are two ways to control the passive film: chemical coloration and electrolytic coloration.

These two methods of controlling the passive film are chemical coloration and electrolytic coloration, and the color produced by these optical interference films is called coloration.

Finally, there is the method of coating the surface of stainless steel with metal ceramics.

There are two mainstream PVD methods used in this process, although they are similar in terms of manufacturing method.

The following is an explanation of how each color stainless steel is manufactured from the material.

Manufacturing method of colored stainless steel

Painting

Painting is the most popular method of producing colored stainless steel.

It is colored stainless steel, but it is commonly referred to as painted stainless steel.

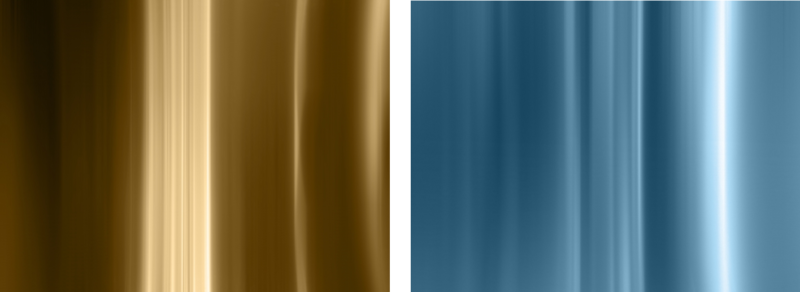

This colored stainless steel (painted stainless steel) can be manufactured in large quantities by stainless steel manufacturers in coiled facilities.

Depending on the type of coating, high durability is enhanced, especially for roofing materials, and the color variation can provide outstanding performance and landscape design.

Types of painted stainless steel.

Although the above is an image of the coating process, the general drafting method for coated stainless steel is to manufacture stainless steel coils at a stainless steel manufacturer and then coat the stainless steel coils. This is a finishing process that ensures stable quality because it is manufactured with mechanical equipment.

Items that cannot be made in coils are manufactured by post-coating.

In this case, there are various coating methods available, some of which are more adherent and durable than others.

chemical coloring

Chemical coloring is the oldest method of producing colored stainless steel other than painting.

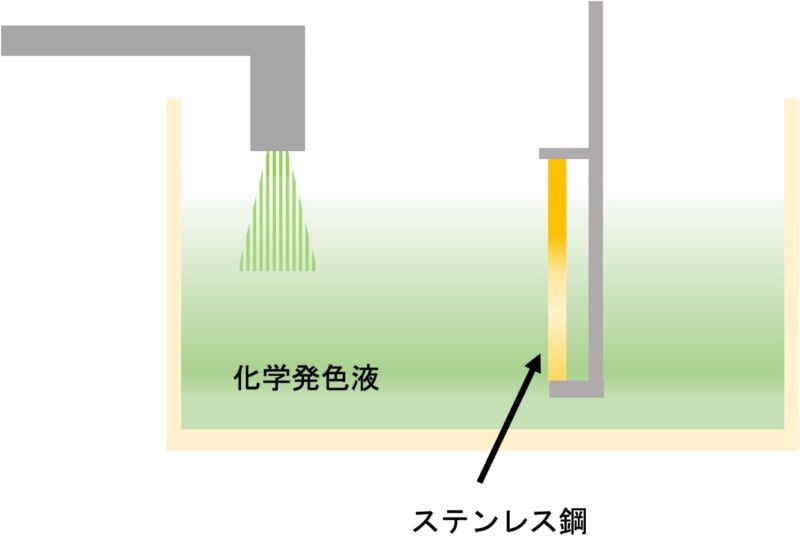

The stainless steel is dipped in a special chemical coloring solution, which causes the passive film on the surface to grow and the color to appear due to the effect of light interference film.

This is a colored stainless steel.

Stainless steel that develops beautiful iridescent hues through chemical coloring.

→ Ororu Corporation(https://ororu-inc.co.jp/)

If you change the angle of the previous one…

Ororu Corporation(https://ororu-inc.co.jp/)

In this way, the color of the stainless steel changes depending on the angle from which it is viewed, which is a characteristic of colored stainless steel that uses optical interference film.

The above is just an image of how chemical coloring is produced. Stainless steel is immersed in this type of chemical coloring solution to grow a passive film.

Imagine oil or soap bubbles floating on water.

This is the principle behind the color of the stainless steel.

We also manufacture colored stainless steel design materials using this chemical coloring process.

This is a water surface stainless steel panel. Please refer to the following link for more information.

If you are interested in this colored stainless steel design material, please contact us for further information.

Mysterious stainless steel in navy blue

electrolytic coloring

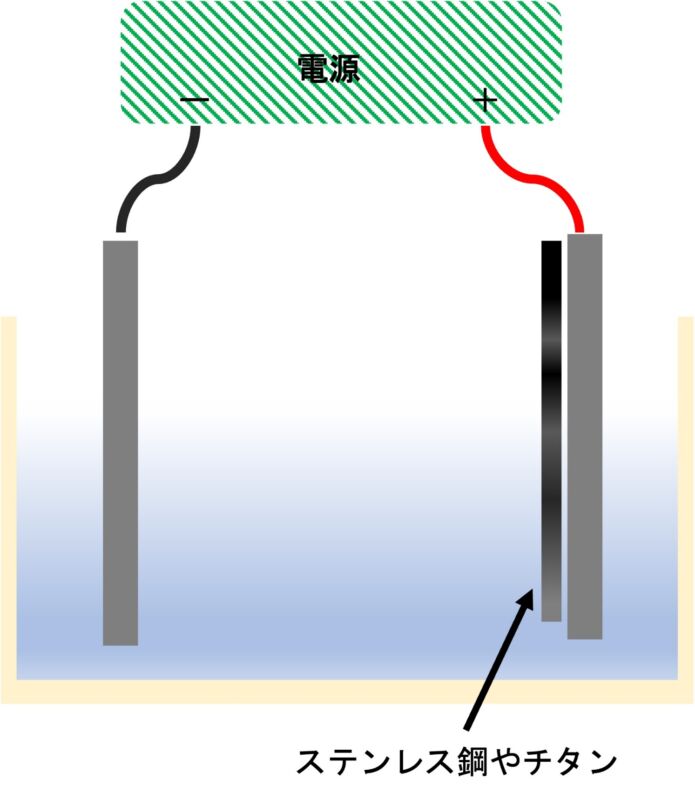

In principle, electrolytic coloring is a technique that uses electricity to produce the chemical coloration described above.

Black is the most famous color for stainless steel, but this electrolytic coloring is used for titanium.

Example of electrolytic coloration of titanium The appearance of iridescence is similar to that of chemical coloration, but the coloration method must be selected according to the material.

By applying electricity in this way, it is possible to obtain an iridescent surface by the reaction in the electrolyte and the growth of a passive film.

PVD (Physical Vapor Deposition)

The last method is to form a thin film of metal-ceramics on the surface of stainless steel using a vacuum system.

Unlike conventional painting, chemical coloring, or electrolytic coloring, this method forms a tough metal-ceramic film on the surface while utilizing the metal substrate.

This technology is widely used in a wide range of applications, from coating tool edges to decorative items (watches, glasses, etc.).

There are two main methods, ion plating and sputtering.

There are two mainstream methods, ion plating and sputtering, but each method is further subdivided, and each manufacturer has accumulated its own unique volume technology.

.png)

On the left is the ion-plating method, which uses the power of electricity to ionize metal from a lump of metal called a target and strike it onto the metal surface.

On the right is the sputtering method, in which a gas called argon is activated and struck onto a metal material called the target, whereupon the bounced ions from the target are deposited on the metal surface.

For example, when a golden hue is deposited, a golden stainless steel is produced.

For more information about golden stainless steel, please refer to the following

Our ion plating technology is also at its best in titanium.

IP Gold Titanium, developed with Nippon Steel Corporation, maintains its majestic appearance and performance even in harsh environments.

If you would like to know more about it, please read the following column article

If you would like to know more, please refer to the following column article. If you would like to know more, please refer to the following column article.

If you would like to know more, please refer to the following article.

Characteristics of Titanium and Durability of IP_Golden Titanium

Finally

The following is a brief explanation of the manufacturing process of colored stainless steel, one of the stainless steel surface finishes.

Colored stainless steel is a type of stainless steel surface finish.

A wide range of choices are available depending on the application.

While retaining the texture of the design polishing process, we believe that chemical coloring, which gives a glossy hue, can contribute to the creation of new spaces.

We look forward to working with you.

<Sales for materials and glass coating liquid>

Sales Division, Toyo Stainless Steel Polishing Co.

Topma Coat Co.