Buffing in stainless steel polishing is a polishing technique in which the surface is coated with abrasives and other materials and the buff is rotated at high speed to polish the stainless steel.

There is a wide range of buffing processes in stainless steel polishing, from those that can be done with DYI tools to those that require large equipment.

In this article, we will provide an overview of the buffing process in stainless steel polishing, including the types of machines used in the buffing process, points to note during the process, and the characteristics of the surface after the process.

If you are considering buffing, please read on, and if you have any questions or concerns, please contact us for consultation or inquiry.

contents

Buffing for polishing stainless steel

A buff is a circular, flexible material made of cloth or synthetic fiber that is attached to a polishing tool to polish metal to a smooth surface.

This buff is also sometimes referred to as a feather cloth.

When the term “polishing” is used in stainless steel polishing, this is almost always the method used to polish stainless steel.

The buff is rotated at high speed to apply abrasives to the surface and then pressed against the stainless steel to increase its shine.

About the machine for attaching buffs

The buffing machine is attached to a variety of machines and equipment, from small tools to stationary tools to large-scale polishing equipment, to polish stainless steel.

First, there is the common grinder sold at home centers.

A grinder is ideal for polishing small areas of stainless steel to make the surface shine, or for polishing welded areas.

However, when polishing a large area or a shaped object, it is difficult to polish the object well, as well as having problems such as unevenness and poor polishing.

In such a case, stainless steel polishing with a buffing machine is used to polish shaped objects with stationary equipment.

This stationary polishing system can polish the surface of stainless steel products with a certain large area or intricate shape.

What is unique about this system is that the number of rotations can be finely controlled and a wide variety of buffs can be used.

The feature of this system is that it is possible to create the optimum polishing process according to the object to be polished.

However, the cost of the equipment is quite high, it requires a place to be placed, and it requires a 200V power supply. Compared to a handheld 100V grinder, this stationary type of polishing equipment is more powerful and has a wider processing range, but it has its own limitations.

So, what kind of equipment is needed to polish a large area of plate products with stainless steel?

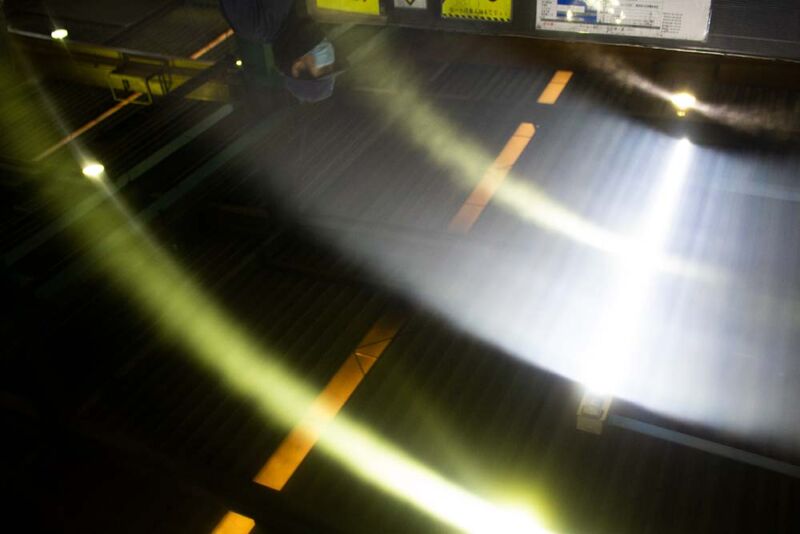

This machine must have a bed that can move the width and length of the plate, and since it moves back and forth, it simply needs to be twice as long.

In addition, since it is a huge mass of motors and controls, including moving motors and buffing motors, it requires a very large space to be placed.

It also consumes a lot of electricity, so it is difficult to operate unless the factory is equipped with large electrical facilities.

In addition, safety measures must be taken so that no one can enter during operation.

View from the back

Buffing width of about 1600mm.

The black roller is the part where the buffing wheel is rotating.

(The black roller is the part where the buffing machine is spinning, and the chain on the left makes it impossible to enter during actual operation.)

View from the front

The buffing roll hits the stainless steel plate in parallel.

As you can see, it is very difficult to finish a flat surface evenly in buff polishing.

One of the reasons why it is so difficult to achieve a uniform surface in buff polishing is that there are so many items to control, such as the balance of the table and pressure, and the unevenness of the buff.

In this way, buffing equipment differs depending on the object to be polished, and it is necessary to assemble an optimal stainless steel polishing method.

Buffed and polished stainless steel surface

Stainless steel that has been buffed will have lines in the direction of the polish, called buff marks.

By changing the hardness of the buffing material, the abrasive, and the direction of buffing, it is possible to reduce the buffing lines and make them look less like lines.

The buffing wheel is like a wheel, so if you make the buffing wheel polish in a certain direction, the lines will appear in the direction of the buffing wheel.

Buffing is performed on a 1219mm wide stainless steel.

A thin, fine buff line is formed in the direction the buff moves.

When buffing a pipe shape, the buff line is basically created in the longitudinal direction.

In the case of circumferential polishing, the buff lines are generated in a spiral pattern around the circumference of the pipe.

Finally

Buffing is a very popular method of stainless steel polishing, ranging from DIY polishing using tools available at home centers to stainless steel polishing using large-scale equipment.

In this article, we have provided a general overview of buff polishing.

If you have any questions, please do not hesitate to contact us.

<Sales for materials and glass coating liquids>

Sales Division, Toyo Stainless Steel Polishing Co.

Topma Coat Co.

https://www.top-macoat.co.jp/