Bead blasting is generally defined as the process of bead blasting stainless steel with glass, zirconia, or other spherical media under air pressure to create a pear-shaped surface.

Although bead blasting is mainly used for decorative purposes, it can also be used for partial processing and gradation expression.

The appearance of gradation in bead blasting differs depending on equipment conditions and the location (indoor or outdoor).

In this article, we will explain how gradation is expressed in the bead blasting process based on examples.

contents

About bead blasting process?

Generally speaking, bead blasting is a process in which beads of glass, zirconia, or other media are blown onto stainless steel under air pressure to create a pear-shaped surface.

For more information

What is bead blasting finish for stainless steel? Its features and case studies!

What is bead blasting finish for stainless steel? Its features and case studies!

What is blasting? Features and Common Problems Explained

Although bead blasting is mainly used for decorative purposes, it is also used for LCD substrate manufacturing equipment and semiconductor manufacturing equipment to provide uniform surface roughness and functionality.

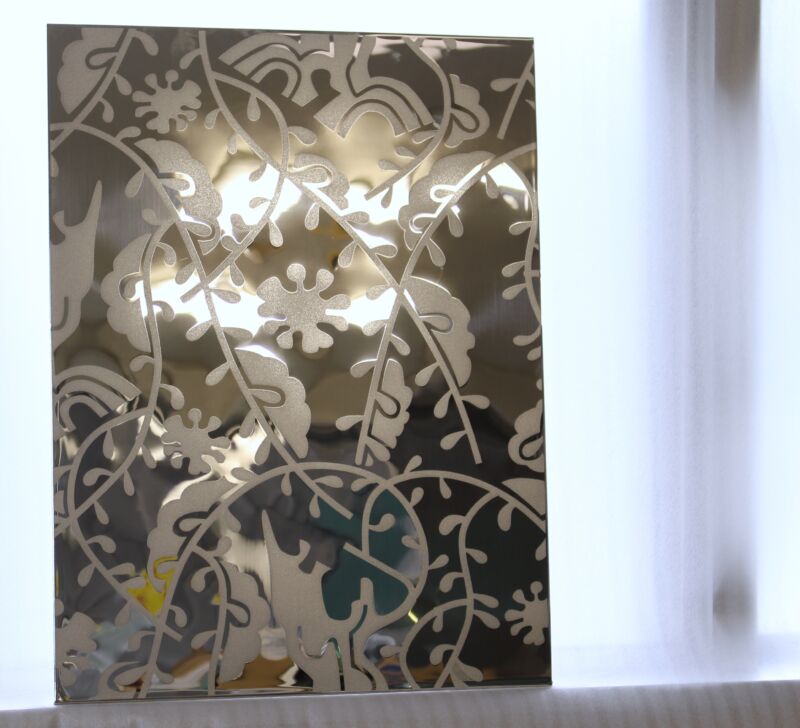

<An example of bead blasting on stainless steel>

Texture drawing by bead blasting process

So how does partial bead blasting work?

This is an example of bead-blasted stainless steel composite plate ALOPLIC®︎SCM with the ancient Japanese pattern “Yukimochi Yanagi”.

The contrast between the mirror-finished and bead-blasted areas expresses the texture of the “snow-covered willow” as if it were floating in the air.

Gradation by bead blasting process

Is it possible to express gradation in the bead blasting process?

What is Gradation?

Gradation is an expression of continuous or gradual change in hue, appearance, effect, or texture.

A gradient is an expression of continuous or gradual change in hue, appearance, effect, texture, etc. A picture of a gradient expression looks something like this.

Gradation expression with different shades gradually becoming darker from left to right.

Gradation in which different shades gradually become darker from top to bottom

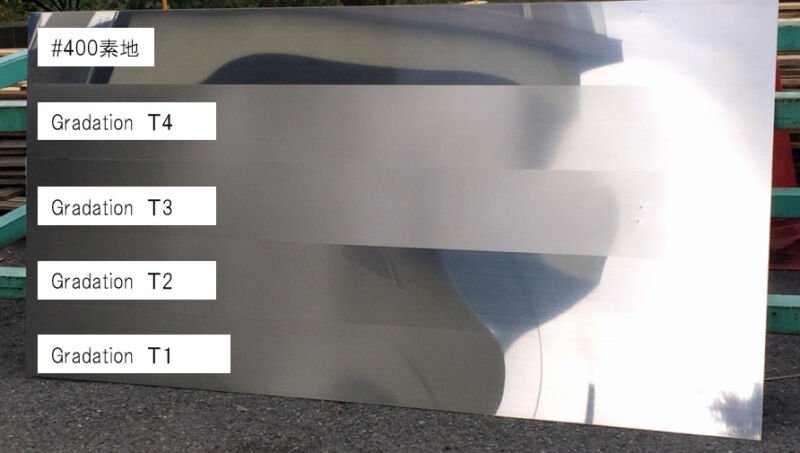

The gradation expression in the bead blasting process will be explained using stainless steel (#400 buffed stainless steel).

In this article, we will introduce the difference in appearance when manufacturing conditions are changed, based on examples of indoor and outdoor use.

Gradation expression on stainless steel (#400 buffed stainless steel)The first step is to use stainless steel to create this gradation.

へのグラデーション表現.jpg)

To make identification easier, gradation in bead blasting is used on #400 buffed stainless steel.

The top one is #400 stainless steel. The buff line can be seen in the longitudinal direction.

The second line (Gradation 2) is a darker gradation.

The third line (Gradation 1) is a gradation aimed at the middle.

The fourth line (Gradation 3) is a thinner gradation in the opposite direction.

へのグラデーション表現2.jpg)

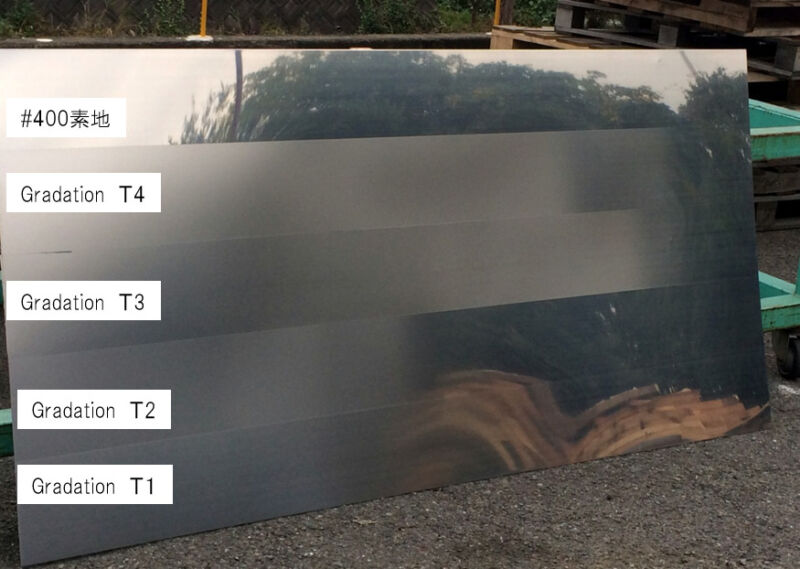

This photo was taken from a different angle.

Texture drawing by blasting

By changing the manufacturing conditions, it is possible to change the position and intensity of the gradation.

This is an example of how gradation can be expressed by varying the equipment conditions.

This is how it will look indoors.

As is often the case, when measures are taken indoors and then taken outdoors, the effect can be obscured.

The reverse is also true, but it is always important to check the appearance of the product indoors and outdoors.

Now, let’s check how it looks outdoors.

Changing the angle, the way it looks outdoors.

You can see that the trees on the surrounding highway are blurred or hidden by the gradation lines.

As you can see, the gradation process using bead blasting allows for a variety of expressions by manipulating the manufacturing conditions (equipment conditions).

Finaly

The first time we used bead blasting to create a gradation effect was in 2013.

Today, it is possible to express gradation effects not only by bead blasting but also by various other surface finishes.

Deeper gradation processing with greater visibility is also possible.

If you are interested, please contact us for further information.

<Sales for materials and glass coating liquid

Sales Division, Toyo Stainless Steel Polishing Co.

Topma Coat Co.

https://www.top-macoat.co.jp/