contents

Introduction to the latest adoption cases and functional points

We would like to introduce you to some of the latest examples of the use of Designing Metal and its functional points.

The following three examples are all made to order. These are manufacturers who have the ability to customise our design metal materials in any material and surface design.

We know that there will be occasions when ready-made products do not fit in, or when we need to order something to reflect the owner’s wishes, or to create a space that has never existed before.

We hope you find the following examples and their manufacturers useful.

(Case 1) The world’s first garage made of 3D stainless steel

The first example is a side slider garage made of 3D stainless steel. Golden 3D stainless steel has been used for the opening and closing of automatic doors, but this is the first time it has been used for a garage.

The garage is a side-slider door structure, which slides in a lateral direction.

The structure and strength of the garage is ensured by the wooden panels on the back, while the 3D stainless steel surface is designed as a decorative cover.

It is therefore possible to install many different types of decorative panels. Or, to take it to the extreme, each panel can be different.

We are told that we have already received inquiries for custom-made garages.

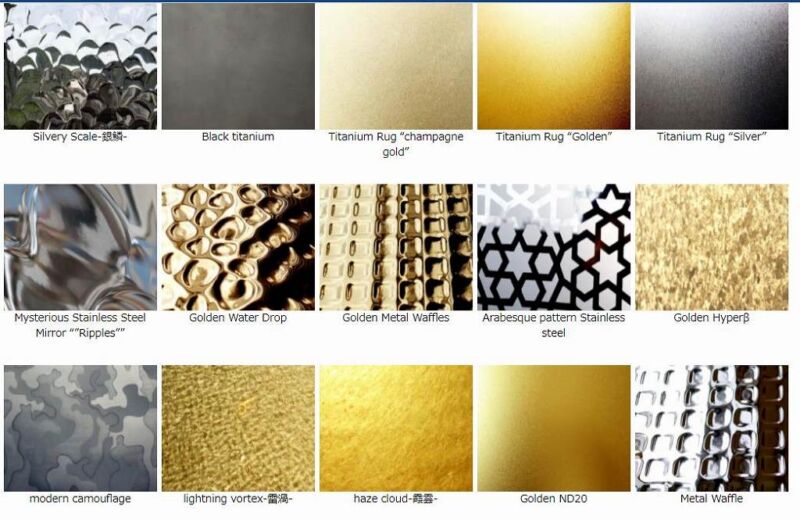

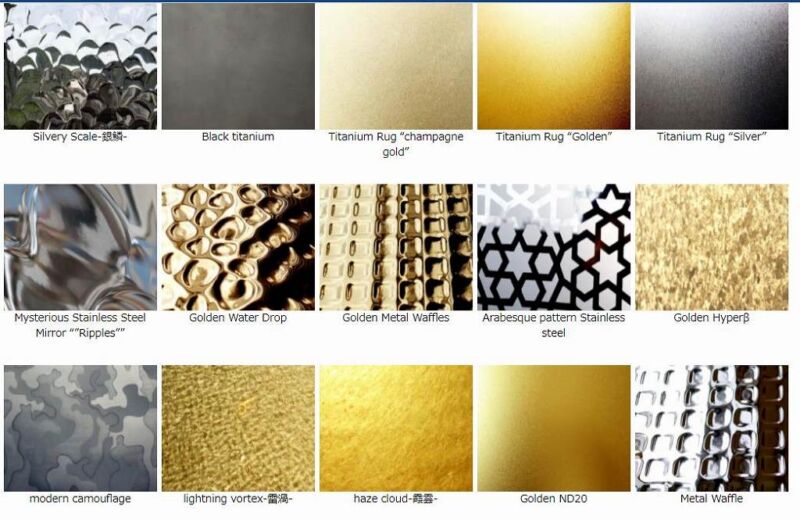

A garage with a choice of many design metals.

Here’s a video of it in action.

It slides beautifully in the right direction.

The movement is smooth and fluid.

The key to garage adoption

The main reasons why we were chosen were

(1) The possibility of customising the design from a wide range of metals to suit the customer’s taste.

(2) The design metal panels are highly scalable, with the possibility of adding logos and laser cut textures.

3) It is a high-end design garage.

(4) The garage can be designed in collaboration with the light, glittering in the daytime with sunlight and glittering at night with lighting.

Thus, at night, the beautiful reflection from the garage surface, illuminated by the lights, awaits the return of the owner.

Meet the garage manufacturers

http://www.wgd.co.jp/

Company profile and business description

Company name: World Garage Door Corporation

Head office 405-1,Shimo-osaba,Yamaguchi-shi,Yamaguchi 753-0212, Japan

(405-1,Shimo-osaba,Yamaguchi-shi, Yamaguchi 753-0212, Japan)

Telephone number 81-83-927-6500

You can contact us directly, or you can contact us for the selection of materials, as in the case of this stainless steel for garage.

We look forward to working with you.

(Case 2) Custom-made kitchen in white stainless steel

The following is a case study of a manufacturer of custom-made kitchens.

This manufacturer has been using our special stainless steel materials for a long time. They have used our special stainless steel materials for many years and for many different projects.

They have recently renovated their showroom with a new type of custom made kitchen.

The main body of the kitchen is made of a special design of stainless steel.

The kitchen body is made of a specially designed stainless steel called “Shines with waves MD”, which is very scratch-resistant and easy to clean.

The white stainless steel has a beautiful white colour that gives it an elegant look.

The kitchen panel on the back is made of “Umeda”.

This product is a tribute to the legendary plum tree “Tobiume” in Dazaifu Tenmangu Shrine. It has an elegant Japanese look, but with the added advantage of being scratch resistant.

The undulating texture of the plum branches is a result of the heterogeneous finish and the natural waves give the impression of a flying plum branch.

This is a very smart looking and very user-friendly kitchen.

The finishing touches are made with great attention to detail.

We work together with this kitchen manufacturer from the material stage, including the production method.

The final polishing is carried out in our factory using the latest equipment and skilled workers.

The entire kitchen is covered with the special stainless steel design “Shines with waves MD”, but it is the top panel that is particularly effective.

The top is subject to contact with many different things. This is why, over time, the number of small scratches increases.

Shines with waves MD is a product that does not suffer from these scratches.

This is an ideal feature for kitchen tops.

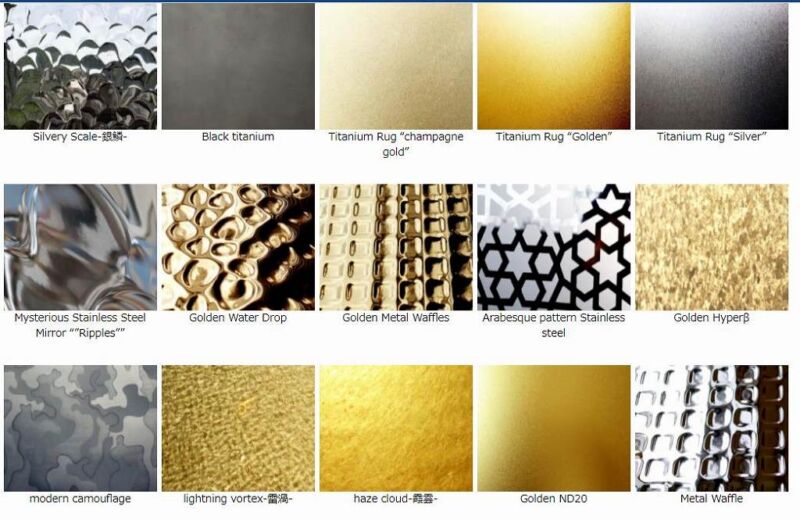

You can also choose from a wide range of metal designs for the kitchen panels and doors.

This custom kitchen manufacturer creates custom-made kitchens according to the owner’s requirements.

They will be happy to respond to your specific design and functional requirements.

A choice of many design metals.

Why use a custom-made kitchen?

The main reasons for the use of white stainless steel design materials are

(1) It is possible to customize the design according to the owner’s preference from a wide range of design metals.

2) The use of white stainless steel prevents metal allergies.

(3) Special processing makes it possible to create tops and kitchen components that are scratch-resistant and easy to clean.

The coefficient of thermal expansion is low and thermal deformation is low.

In this way. The design of stainless steel is not just about form, it is about function.

Custom kitchen manufacturers

Custom-made kitchen manufacturers available in Castaic

http://prono.co.jp/

Prono

2-4-7 Wakamiya, Higashi-ku, Fukuoka City

tel81-92(672)3663

fax81-92(516)3137

No holidays 10:00-18:00

If you have any questions, please feel free to contact us directly.

You can also contact us if you would like to find out more about the materials used for kitchen panels and tops.

We look forward to working with you.

(Case 3) Custom-made furniture from Designing Metal

Our last case study is for a manufacturer of custom-made furniture.

We have already introduced them in our newsletter, but now they have a new catalogue and price list.

We have already mentioned them in our newsletter, but now they have a new catalogue and price list.

However, this custom-made furniture manufacturer is able to take custom orders from a single item.

Not only can they change the shape of the furniture, but they can also change the metal design and materials used.

Let us introduce you to them.

Exhibition at Hakata Hankyu from 18 to 23 August 2021.

Exhibition at Hakata Hankyu from 2021.8.18 to 2021.8.23.

Chair Table (small) Console Hanger stand

Chair Table (large) Console Plant base

View table (large) Hanger stand Plant base

Clocks

This company produces furniture using design metal with the concept of “making metal more everyday”.

At the moment, their products are mainly for living spaces, but they can also be used for condominiums and commercial contracts. The furniture is made from a variety of materials with a high level of design.

The strength of this manufacturer is that they are able to customise their products to the owner’s requirements.

We are very pleased with their approach to manufacturing from the very first unit.

A choice of many design metals.

The key to the adoption of custom-made furniture

The main reasons for choosing stainless steel design are

(1) The possibility of customising the design from a wide range of metals to suit the owner’s taste.

(2) The metal is easy to process and embody the designer’s image.

(3) The material sales system of our company allows us to take into consideration the material procurement by our subsidiary company, Topma Coat, even if the order is for cut boards.

(4) The passion of the president of the order-made furniture manufacturer.

As you can see, the biggest reason for our success is the passion of the president of the company, and we are doing our best to contribute to this passion.

Custom furniture manufacturers

![]()

https://www.yamamoto-ss-katsuragi.jp/

Company name: Yamamoto Seisakusho BASE Co.

1538 Oaza Mitani, Katsuragi-cho, Ito-gun, Wakayama 649-7133 Japan

TEL 81-736-22-3161

Bland:Metalab

https://metalab.jp/

Click here to download the catalogue → S210820_metalabweb

You can also contact us directly with your enquiry.

You can also contact us if you would like to discuss the materials used to make custom-made furniture for contract and private homes.

We look forward to working with you.

Finally

Here are some recent examples.

While we are always happy to discuss panel sizes, shapes and configurations for interior and exterior architectural and commercial projects, we have not been able to provide the same level of service for equipment and facilities such as garages, kitchens and furniture.

We are now accelerating our collaboration with fabricators in the architectural field, manufacturers of appliances and equipment, and artists working in the field of art, in order to help you in your work.

We would like to continue to expand our circle of collaborators with manufacturers, installation companies and artists.

We look forward to working with you.

Finally, if you have any trouble in dispersing your purchases, please feel free to contact our subsidiary sales company, Top MaCoat Co.

<Sales Department of Toyo Stainless Steel Polishing Industry Co.>

Top MaCoat Co.