contents

Differences in corrosion resistance by metal type

The term “corrosion resistance” can be used to describe a wide range of performance depending on the corroded object.

Some metals have the ability to withstand environments such as salt-damaged areas and acid rain.

For example, taking seawater as an example, platinum and gold are completely unaffected. The same goes for titanium.

However, stainless steel will rust depending on the grade of steel.

The same is true for copper-based materials and aluminum.

However, even titanium, which is resistant to seawater, will corrode in an environment such as hydrogen fluoride.

Gold also dissolves in royal water (an orange-red liquid made by mixing concentrated hydrochloric acid and concentrated nitric acid in a 3:1 volume ratio).

So, this time, we will explain the corrosion resistance when used in a general environment. The explanation will be given from the perspective of outdoor design building materials used in inland areas and areas near the sea.

When used inland

Many gold storehouse materials can be used in inland areas far from the sea.

This time we will exclude metals that are to be overcoated with paint.

This is because painting is dependent on the performance of the resin coating, which in turn is dependent on the corrosion resistance of the paint film rather than the corrosion resistance of the metal.

Commonly used metals outdoors are

Stainless steel, aluminum, titanium, and copper.

Copper is most commonly used for the roofs of temples and shrines.

The original shade is that of copper, but over the years, the surface is protected by a green rust called green rust. Like the passive film of stainless steel and titanium, it holds back the progress of corrosion.

In contrast, when the copper sheet becomes blackish, it becomes copper carbonate, and corrosion progresses.

Recently, acid rain has had a strong impact on the environment, making it difficult for natural green rust to form.

Next is aluminum, but since aluminum by itself does not prevent corrosion, it is anodized and in some cases painted.

This also depends on the performance of the plating and coating rather than the performance of the aluminum.

Therefore, I think it would be better to ask plating and coating manufacturers about the outdoor use of aluminum.

Next is titanium.

In inland areas, there is no need to worry about corrosion at all.

The only thing to watch out for is discoloration caused by flying contaminants.

Basically, there is almost no significant loss of appearance.

Golden titanium roof.

For more information, click here.

【Characteristics of Titanium and Durability of IP_Golden Titanium】

Characteristics of Titanium and Durability of IP_Golden Titanium

Next is stainless steel.

Basically, general-purpose stainless steel SUS304 is used.

In inland areas, there is almost no problem.

However, even in inland areas, corrosion may occur if the area is near hot springs or volcanoes.

In addition, as is often the case, rust can occur near rivers where water from the sea flows back.

In addition, places near roads where anti-freeze is applied in winter will also get rust.

SUS430, which is used for kitchen and interior decoration, unfortunately rusts outdoors, so don’t worry about the fact that it is stainless steel.

This is a handrail for the main hall of a shrine in the center of Fukuoka City.

It is manufactured with general-purpose stainless steel SUS304.

However, when SUS430 is used to make panels for outdoor use, rust occurs even in inland areas.

Stainless steel is not “rustproof” but “rust resistant”.

Steel grade means that stainless steel is steel. Steel is made by mixing iron with a variety of rare metals. A strong oxide film is formed on the surface of stainless steel to prevent oxidation and corrosion.

The better the grade of steel, the higher the content of rare metals and the more resistant to corrosion it is.

SUS430, which is mainly used for indoor applications such as kitchens, cannot maintain its corrosion resistance when used outdoors.

The better the grade, the longer the period of time before rusting.

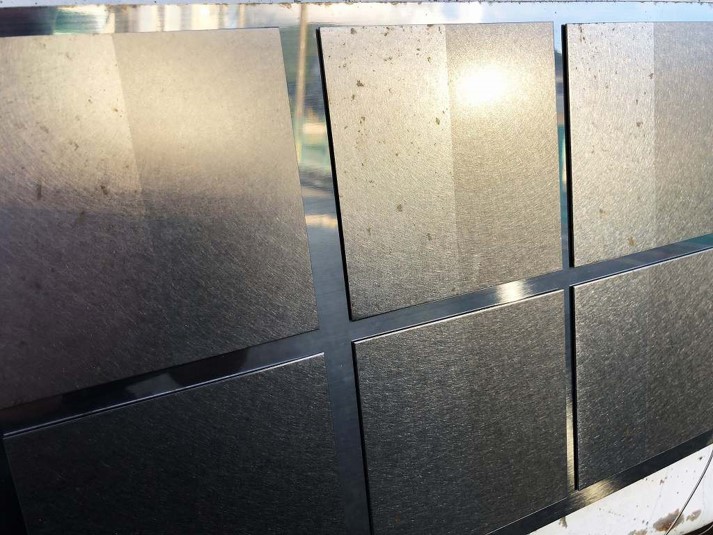

Inland area Dazaifu City, Fukuoka Prefecture Weather resistance test of SUS430 metal panel on factory wall.

As you can see, there is a large amount of rust.

For more details, please refer to

【How to choose a stainless steel exterior wall? From what’s new to what to watch out for!】

How to choose a stainless steel exterior wall? From what’s new to what to watch out for!

When used near the sea

In areas close to the ocean, sea salt particles fly in.

Hence, painted surfaces, plating, and general-purpose stainless steel will all corrode.

Titanium is the most resistant material here.

Titanium has a salt resistance comparable to that of platinum. This is why it is so widely used in important parts such as submarine structures.

Stainless steel also delays the onset of rust by selecting the right grade of steel.

In areas relatively far from the sea, SUS316 is commonly used. This is a molybdenum blended stainless steel.

As you get closer to the sea, the grade of steel must be greatly improved.

The grade of stainless steel should be selected based on the intended use and location.

The exterior walls of the building, which is located relatively close to the ocean and near a river where sea water comes up in the form of a tidal current, are made of corrosion resistant steel grade ferritic stainless steel NSSC220M after checking the initial rusting condition of the surrounding area.

It is very important to select the appropriate stainless steel grade for the surrounding environment.

Other environments (volcanoes, hot spring areas, etc.)

In the natural world, environments that corrode metals include volcanoes and hot spring areas.

In addition, rust can occur if there are places nearby where iron powder is flung up.

When using metal materials outdoors, it is important to carefully observe the surrounding conditions before selecting the materials to ensure long life and reduce maintenance costs.

Simple measures

If you have already installed it or put it in a place where you can’t remove it, the solution is to paint it.

However, there may be some inconveniences such as the inaccessibility of painting or the change in impression or design due to coloration.

Long-term durability depends on the usage environment, but if you use a coating method that can be easily reapplied several times, rusting will be largely prevented.

For example, our MaCoat GC coating can be applied easily.

It is effective in inhibiting rust even outdoors.

The right side is the Macoat GC coated part, and the left side is SUS304 as is.

The difference between the coated and uncoated parts is remarkable.

The difference between the coated and uncoated areas is very noticeable. If you have not selected a steel grade for various reasons and have completed the installation, you may want to consider post-coating as an option.

Corrosion resistant coating agent Macoat GC

For more information, please see → Click

Finally

Corrosion resistance varies greatly depending on various locations and environments.

In this article, we introduced corrosion resistance mainly in the sea, which is a harsh natural environment, but in reality, it is necessary to consider corrosion resistance in special gas environments such as volcanoes and hydrogen sulfide generated in hot spring areas.

In fact, it is necessary to consider corrosion resistance in special gas environments such as volcanoes, hydrogen sulfide generated in hot springs, etc. In addition, there are many different situations such as chemical plants and environments where corrosive liquids are suspended.

Checking the corrosion resistance of each type of steel, especially stainless steel, and carefully examining the [steel grade] before use will ensure a safe and secure environment.

For more information on stainless steel grades, please feel free to contact us.

Although not mentioned in this article, corrosion resistance also varies depending on the polishing process, so it would be better to consider a combination of stainless steel grade and design polishing process.