contents

The surface of the metal used in the design

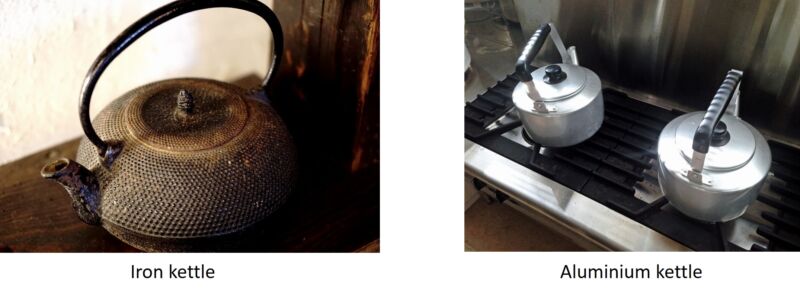

There are a number of products made from metal that are all over the world.

The most familiar of these is steel, followed by aluminium.

Most iron products are painted or filmed, and iron is rarely used in its original state.

Aluminium can be anodised, painted or colour anodised, as is the case with window sashes.

Then there are the stainless steel products.

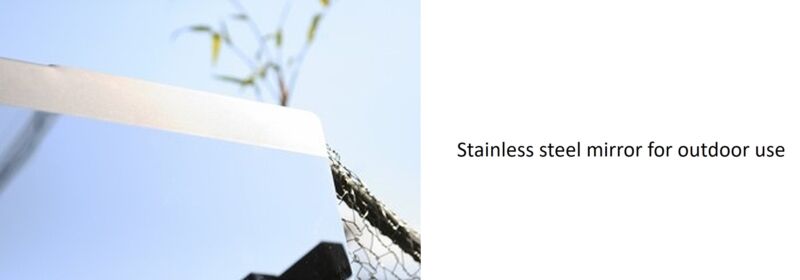

Stainless steel is a “rust resistant metal”. It has a tough passive coating which makes the surface resistant to rust. This is why it is often used in water and outdoor applications.

Other materials include titanium, copper and brass.

Each metal has its own characteristics.

Copper oxidises over time, giving it an antique, dull appearance.

Stainless steel and titanium, on the other hand, retain their brilliance.

Stainless steel for buildings, monuments and transport vehicles

A large number of stainless steel products used outdoors are buffed and polished. This is partly for aesthetic reasons, but also because rust resistance and cleanliness are important.

Buffing is a surface design that is very easy to use due to its ease of polishing and processing, as mentioned in the previous column.

This is why it is widely used in a variety of applications and industries.

→ Reference: What is stainless steel polishing?

A #400 buffed finish is often less than a buffed mirror finish and will also have a streaked pattern called a buff line.

These streaks can be unattractive to the design of a building or interior.

Therefore, when the design of a product with such buffing streaks is not suitable, it is often mirrored in stainless steel.

When mirrored stainless steel is a problem

When used indoors, this is less of a problem, but when used outdoors, stainless steel mirrors are very reflective, bouncing light back and forth, causing glare and thickening the mirror as it reflects heat.

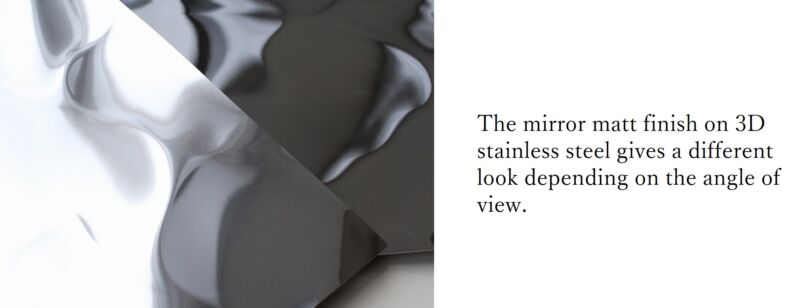

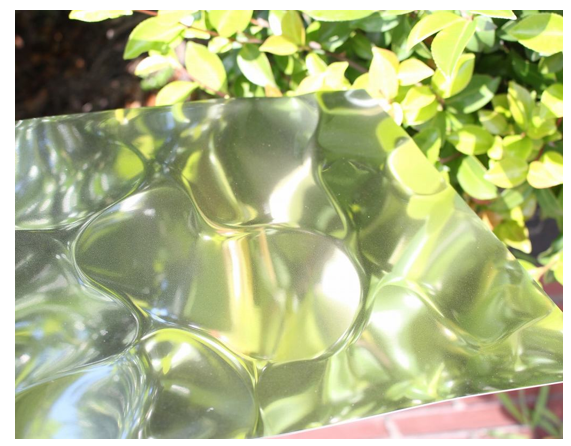

Therefore, instead of working with mirror finishes only, we often use textured or 3D surfaces to diffuse the light.

This method requires the placement of textures and patterns which cannot be used if they are not compatible with the design.

In order to reduce the reflection of light, we use a matt finish, which is more harmonious.

What is matte finish?

In general, the term matte refers to spray paint, rough plastic or uneven printing.

These days, you will sometimes see cars with a matte finish.

I don’t know if it’s a matte coating or a matte film, but it gives a special impression.

It looks difficult to clean. It also gives the impression that scratches will be more noticeable.

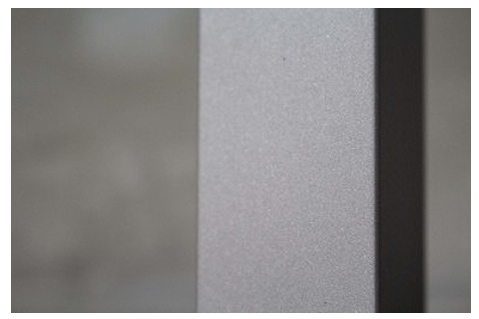

A similar matt finish can be achieved on stainless steel using a sandblasted finish.

As with the matt finish on cars, this finish is very difficult to maintain as it is prone to staining and scratching.

→Click here for sandblasting products

For this reason, we recommend that sandblasted products be coated with Macoat_GC as a final finish.

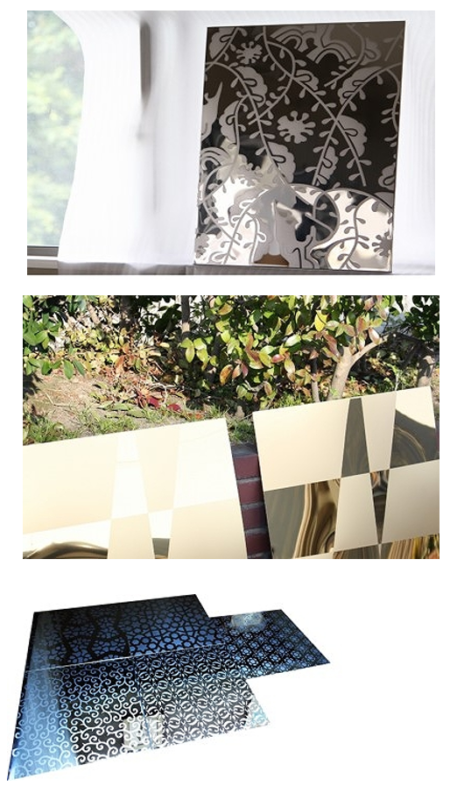

About the matt finish of mirrored stainless steel

A matt finish that retains the good qualities of a mirrored surface, while reducing reflections and glare.

It is a process that allows a subtle adjustment of the gloss level and is characterised by a subtle reflection.

This is a special process which reduces reflection and shine while maintaining the lustre of a mirrored surface as much as possible.

Our product name Fine Mist is a typical example.

Can you see this subtle reflection?

The surface looks like it has been covered in water vapour in the round, retaining the characteristics of mirrored stainless steel.

The reflection of light is also greatly reduced when the matt finish is applied to this extent.

The reflection in 3D gives a very fantastic impression.

Finally

Apart from matt finishes, it is possible to achieve, for example, a semi-glossy finish with hairline or vibration finishes.

The appearance of stainless steel can be changed in many ways.

Depending on the application, the location and the environment in which it is used, it is possible to change the design.

Stainless steel can be used to enhance your design image from both a functional and a design point of view.

The same applies to titanium.

We look forward to working with you.

Translated with www.DeepL.com/Translator (free version)