The expression “stainless steel polishing” is often heard in the hardware industry.

This stainless steel polishing has a wide range of designs and functions, and the industry is diverse.

In general, the expression “stainless steel polishing” often refers to buffing and polishing.

Buffing refers to polishing by rotating a cloth-like object, such as a sisal buff, and applying it to the object to be polished.

How to make buffing plate material

Why do we polish?

→Look at this.

Now, let’s look at the other aspects of stainless steel polishing.

contents

Various types of stainless steel polishing

The most versatile decorative stainless steel polishing Hairline

When it comes to polishing stainless steel sheets, buffing is the way to go.

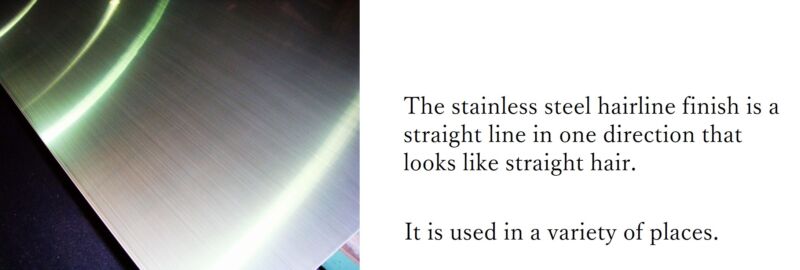

The most popular type of stainless steel polishing for decorative purposes is hairline finishing.

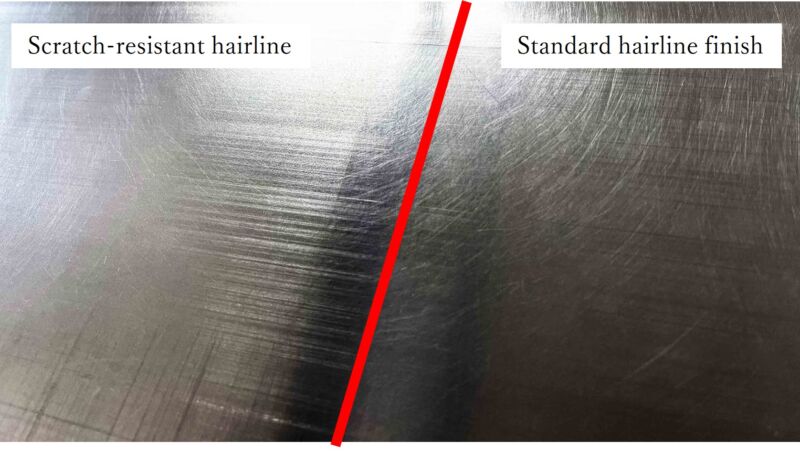

One problem is that scratches that intersect with the polished lines of the hairline will look very bad. We do not recommend using it for the top panel, but if you must, we can suggest a hairline that is less prone to scratches.

If you use ordinary hairline for the top panel, it will be covered with scratches like this. If you have to use hairline, we recommend you to use scratch-resistant hairline. For more information about stainless steel hairline polishing, please refer to the following

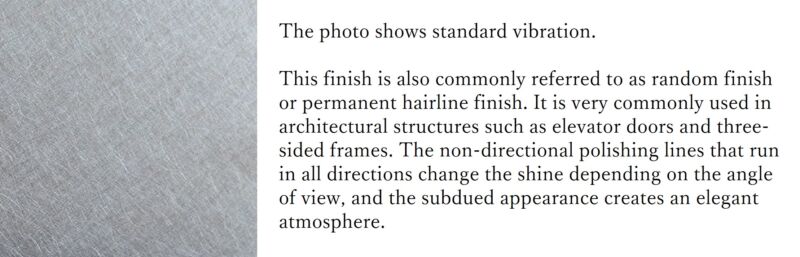

Versatile design stainless steel polished finish Vibration finish

The vibration finish can be seen in many places nowadays. This finish is often used next to the hairline finish in the design finish of stainless steel polishing.

The first thing that the expression “all-purpose” means is that it is easy to process. The difficult point in processing polished stainless steel products is weld correction.

Buffing and hairline finishing are relatively easy, but vibration finishing is comparably easy. While weld correction for mirror and blast finishes is extremely difficult, vibration finishes can be done relatively easily for any shape. In addition, depending on the specifications of the vibration finish, there are vibration finishes that do not have noticeable scratches, expanding the range of applications.

In terms of maintenance, the non-directional polishing makes cleaning easy. This is the reason why it is called a universal product.

For other information on vibration finishing, please see also

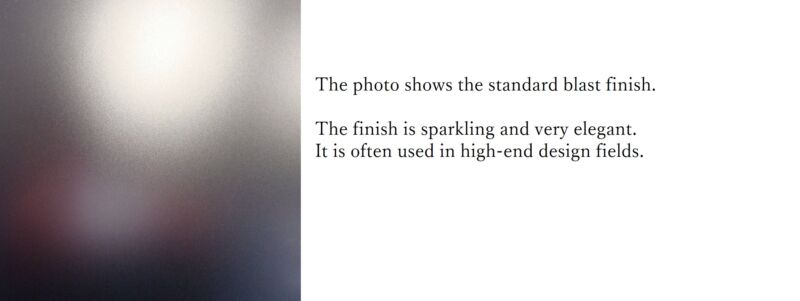

Elegant but difficult to process blasted finish

Blast finishing is a method of decorating by spraying glass, sand, minerals, or metals as a projectile. It is used in a variety of applications. Like painting, it is just spraying. However, this is the most difficult finish to achieve.

The reason why blast finishing is so difficult is that it is extremely difficult to correct welding. In case of on-site repair, extensive curing is required, and it may be cheaper to rebuild.

In contrast to its elegant and beautiful appearance, processing is extremely troublesome.

The luster of stainless steel varies depending on its surface condition.

For blast-finished plates, care must be taken to avoid machining scratches.

When creating processed products, the order in which they are finished is very important.

Our company offers the best stainless steel blasting products based on our long years of know-how, so please let us know in advance what you want to make or for what purpose.

For other information on blast finishing and polishing, please see also.

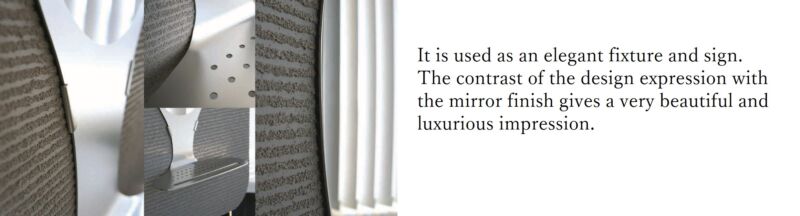

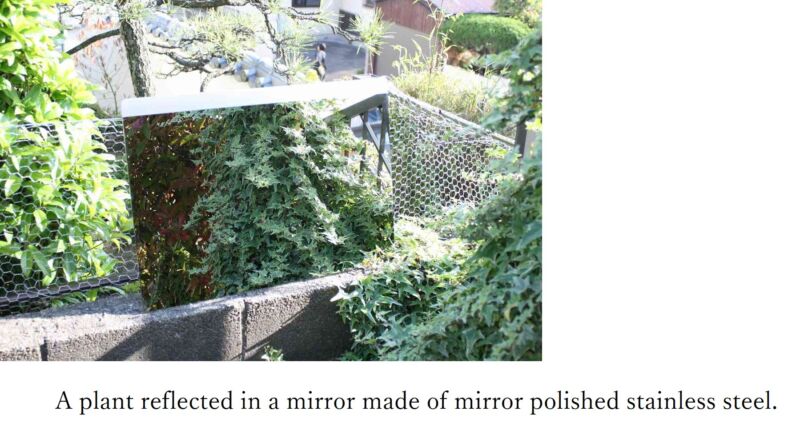

Mirror-like design, mirror finish

Mirror finishes were used in a great many buildings during the bubble economy in Japan.

Today, it is a finish that is rarely seen on buildings. Since using mirror finishes outdoors as they are can cause reflection pollution, the use of this finish has changed over time.

Currently, it is used in areas where the area is not so large, such as fixtures, artwork, three-sided frames of automatic doors, and fittings.

On the other hand, the surface of mirror finish is extremely smooth. Therefore, it is resistant to rust.

It is also a very gorgeous finish, making it an ideal design expression for signs.

Recently, new spatial designs have been created by using 3D surfaces that take advantage of the solemnity of the mirror surface to diffuse light and change the reflection.

For other information on mirror finishes, please see also

Finally.

When people think of stainless steel polishing, they tend to think of buffing.

However, there are five types of stainless steel polishing, including buffing, hairline, vibration, blasting, and mirror finish, even for orthodox finishes.

Each of these finishes has a wide range of variations depending on the application and design.

We will be able to provide you with a design and function that will satisfy you if you let us discuss with you the intended use, environment, and imagined space design.

Stainless steel polishing is a very creative finish with a high degree of freedom.

We look forward to working with you.