contents

Titanium can be processed in a variety of designs!

For design applications, titanium is strong, lightweight, extremely rust-resistant, and beautiful. It has excellent characteristics such as “high strength,” “light weight,” “very rust-resistant,” “beautiful,” and “resistant to thermal expansion. We at Toyo Stainless Steel & Polishing Co., Ltd. express our customers’ “ideas” with beautiful designs that take advantage of the characteristics of titanium.

For design applications, titanium is strong, lightweight, extremely rust-resistant, and beautiful. It has excellent characteristics such as “high strength,” “light weight,” “very rust-resistant,” “beautiful,” and “resistant to thermal expansion. We at Toyo Stainless Steel & Polishing Co., Ltd. express our customers’ “ideas” with beautiful designs that take advantage of the characteristics of titanium.

What is titanium, anyway?

By the way, what is titanium? Titanium is a metal with the element symbol “Ti”.

Compared to iron and aluminum, titanium is lighter, stronger, more rust-resistant, and has amazing corrosion resistance.

Another feature of titanium is that it does not cause metal allergies, making it a safe and reliable material.

In terms of design, titanium has excellent scratch resistance and can be used to express colors in majestic materials.

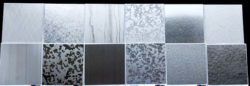

Depending on the processing method and material color, various designs are possible.

Today, I would like to clear up some of your misconceptions about titanium materials.

Are you misunderstanding titanium?

What is your impression of titanium?

“Isn’t it expensive?”

“Is it even available?

“Isn’t it difficult to process?”

That’s a misconception, folks!

Isn’t it expensive? →No, it’s not expensive!

Titanium, with its excellent functionality and design, is certainly more expensive than other metal materials such as stainless steel.

However, we can strike a balance between functionality and design and cost.

The weight of titanium is two-thirds that of stainless steel, and the key is to process it thinly.

For example, we process titanium to a thickness of about 0.3 mm and

For example, we process titanium to a thickness of about 0.3 mm, and reinforce the back with stainless steel to ensure the strength of the titanium panel.

It has unparalleled corrosion resistance and compatibility with the human body, properties that no other metal has.

We hope that you will consider balancing the cost of the product.

Are they distributed in the first place? →We have a full distribution system!

Now, let’s look at the distribution system.

At present, Nippon Steel Corporation is building a system for the wide use of Designing Titanium TranTixxiiⓇ.

TranTixxiiⓇ for a wide range of applications.

Therefore, the problems of distribution, small-lot handling, and delivery time have been solved.

For more information about TranTixxiiⓇ,

please contact →→→→→ For more information, click here.

Isn’t it difficult to process? →It can be processed with a high degree of design!

Titanium can be processed in a variety of design processes such as cutting, bending, welding, polishing, and panelizing.

Any design processing that can be done on stainless steel can be done on titanium!

cutting

Titanium can be cut by YAG laser cutting machine or fiber laser cutting machine.

We can cut and process titanium to the size requested by the customer.

Highly expressive designs are possible.

“I heard that lasers don’t cut! I’ve heard that lasers can’t cut!

YAG laser cutting machine or fiber laser cutting machine can be used.

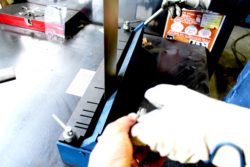

The photo above is a YAG laser cutting machine.

Nowadays, many processing companies have their own processing equipment.

bending

Titanium alloy, with its high hardness, can crack during bending.

However, the design-oriented titanium we process is pure titanium with 99% purity. It can be bent without cracking by general-purpose bending machines or manual bending, enabling a variety of designs.

There are many bending machines in the world, so it is not an exaggeration to say that you can bend almost anything.

However, here is a caution

Titanium alloy is very hard, so it is possible that it may break.

However, designing titanium, which is used for building materials, interior, exterior, fixtures and products, is 99% pure titanium.

Therefore, it can be used for

As you can see, it can be easily bent by hand bending equipment.

welding

Welding of titanium is possible if the titanium is not oxidized.

In order to prevent oxidation, inert gas is applied when welding.

Welding is possible regardless of plate thickness, from thin to thick.

Welding expresses the high quality of design.

The next question is, “Welding is a big hassle.

This is not difficult as long as you keep in mind the point of “not allowing oxidation.

In other words, it is not difficult to weld as long as you apply “inert gas Argon” while welding.

First, let’s talk about laser welding, which is used to weld ultra-thin sheets and thin plates.

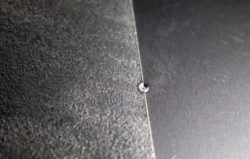

In the photo on the right, the laser welding points are the “pots”.

This is a device like the one on the left, and you work while watching the screen.

Welding is possible up to very thin materials.

It may be a little difficult to see, but argon is emitted from the welding head of the Tig welding machine.

(*”Argonizing” means spraying argon gas on the area to be welded.

Next, a Tig welding machine for welding a slightly thicker plate

This is basically the same as laser welding.

Modern machines (the device on the back) are digital and can be set in various ways.

Adjusting the settings to suit the thickness and quality of the plate will result in a beautiful finish.

Of course, as with stainless steel, the welded area can be polished for a beautiful finish.

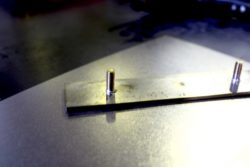

The next step is to weld studs to fasten bolts.

The photo on the right shows a stud bolt, a bolt with threads, attached to a board.

The photo on the left shows the stud bolt being struck with a stud bolt welder.

This is also the same as using Argon.

It is often said that spatters fly, but this can be mitigated by devising the working conditions.

Polishing and panelizing

By adjusting the processing speed and polishing equipment, design processing by polishing titanium is possible.

Designing titanium surface with various polishing processes.

Some adjustments are required for processing speed and polishing equipment.

However, general-purpose buffing and polishing can be done easily.

The same applies to panelization.

<Reference

Titanium wall art panel

A golden metal carpet that marks time

The timeless golden wall “Hexagon”

Finally.まとめ

What do you think?

Titanium, especially “Designing Titanium TranTixxiiⓇ”, is a very easy metal to process.

The required properties are excellent, and its design can be dramatically improved by any design polishing process.

Best of all.

It can be used as it is polished (shaved).

Titanium can be used outdoors, near the sea, or in chemical plants without painting, plating, or coating.

The range of applications is increasing with the improvement of design.

Please take a look at our products.

We look forward to working with you.

(*Please feel free to contact us. (* Please feel free to contact us and request samples!