The texture of metal is a wonderful thing.

Each material has a different luster, texture, and tactile feel, and even if the surface is polished in the same way, the appearance will be different.

We value the materiality of metals and hope that beautiful stainless steel and titanium will be used in many situations. Therefore, we would like to “let people know more about stainless steel! ”Let’s get to know titanium better!

With this in mind, we will continue to introduce the advantages of each metal. Thank you for your continued support.

This time, I’d like to introduce stainless steel.

Today, I would like to talk about the material and the polishing process.

Stainless steel grades (The composition of stainless steel changes depending on where it is used and what it is used for. This type is called a steel grade). There are many different grades of stainless steel, but in the first state there are two main types.

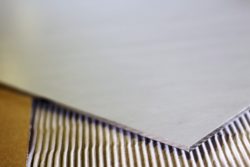

Cold-rolled and hot-rolled.

The surface condition of each is as follows: cold-rolled material has a smooth surface.

The surface condition of each is as follows: cold-rolled material has a smooth surface.

Typical base metal finishes are NO.2B (commonly known as 2B). 0.3mm to 6.0mm are the usual thicknesses available. The standard sizes are 1000mm wide, 1219mm wide, and 1524mm wide.

There are different lengths, but the general standard stock is 1000mmx2000mm 1219mmx2438mm 1524mmx3048mm.

The most commonly used polishing method for 2B material is #400 polishing. #400 polishing is commonly referred to as buffing, and is used in a variety of places.

The most commonly used polishing method for 2B material is #400 polishing. #400 polishing is commonly referred to as buffing, and is used in a variety of places.

For example, it is used for food machinery, kitchen equipment, kitchen walls, exhaust ducts, kitchen sinks, and hand washing areas. This finish is also used for parts of semiconductor manufacturing equipment and tanks in chemical plants.

As you can see, it is an easy-to-use polishing product used in a variety of applications.

In contrast to cold-rolled and dark-rolled materials, heat-sensitive rolled materials have a rough and coarse surface. This roughness and matte surface is sometimes used as a design, and is sometimes seen in the Tokyo metropolitan area. The name of this hot-rolled material is NO.1. It is available in thicknesses from 3.0 mm to about 100 mm.

It is available in a wide range of sizes, up to 3000mmxL, but it is usually purchased in cut pieces.

This material has to be ground on the surface when it is polished. This is a very time-consuming process, but it gives the design an air of dignity.

Now, a variety of polishing finishes can be created by utilizing this base material.

We would like to provide useful information in the next issue.

Thank you for your cooperation.