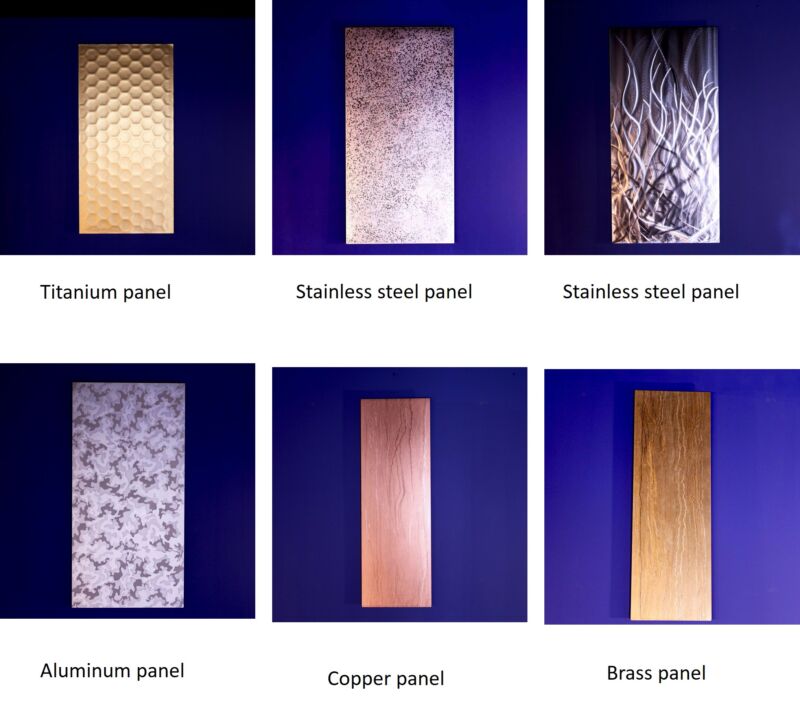

There are many types of metal panels. They are made of steel, aluminum, stainless steel, titanium, copper, brass, etc.

Depending on the design and application, a variety of blue metals are used. Metal panels are used for both interior and exterior applications.

They are used in a variety of applications such as walls, ceilings, and floors.

In this article, we will explain the different types of metal panels, and then introduce stainless steel.

contents

What types of metal panels are available?

Each metal panel has its own unique design with many variations such as plating, painting, chemical coloring and design polishing.

While considering the characteristics of the material, it is important to consider indoor and outdoor applications.

In addition, the location of use is selected in terms of strength, corrosion, and discoloration.

In addition, whether or not the material can be repaired is also a factor to consider in some cases.

What are the features of stainless steel panels?

We would like to introduce the stainless steel design panel, which has both corrosion resistance and design among metal panels.

We will introduce the stainless steel design panel, which is advantageous in terms of both corrosion resistance and design, as well as maintenance.

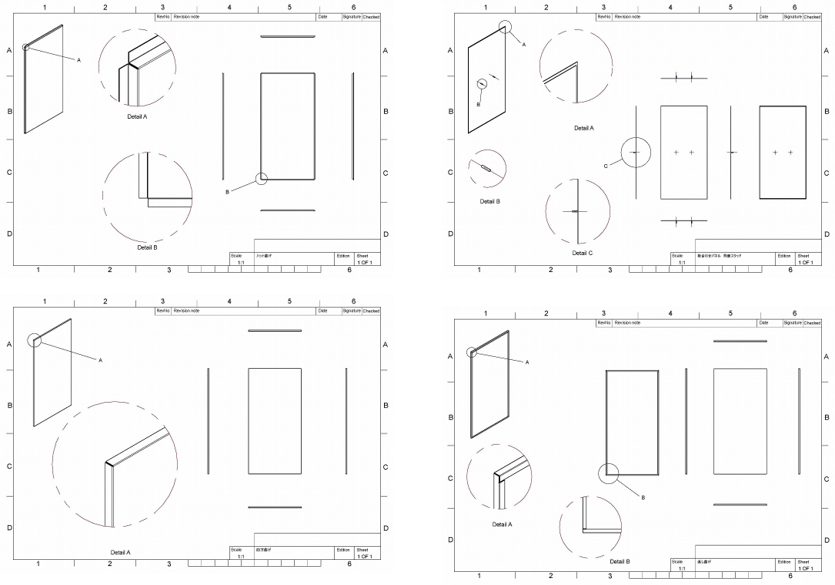

Workability of stainless steel design panels

Stainless steel is an extremely easy metal to work with. Complex processing and welding can be done freely. It is also easy to modify welded areas, which allows for excellent design expression.

It is also very strong, so it can be manufactured with openings.

The openings can be used not only for the necessary lighting and exhaust vents, but also for hollowed-out panels with design textures.

Corrosion resistance of stainless steel design panels

General-purpose stainless steel (SUS304) is cost effective for inland areas and indoor applications, and its tough corrosion resistance prevents much rusting. However, for coastal areas close to the sea and interiors such as water features, it can be adapted to almost any environment by changing the steel grade of the stainless steel panel.

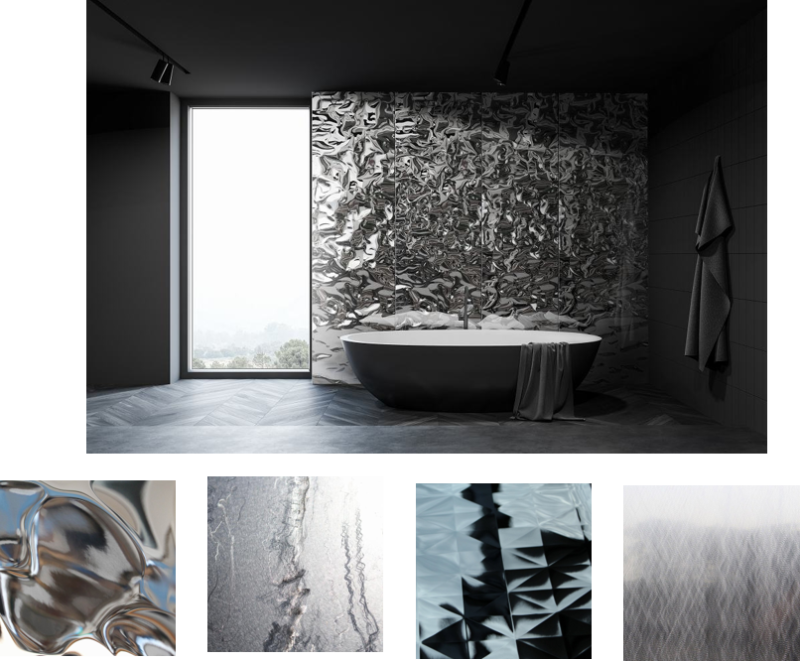

In addition, white stainless steel panels, which have both corrosion-resistant functionality and design features, contribute to creating spaces with a new aspect of stainless steel.

Excellent heat resistance and fire prevention properties

The melting point of stainless steel is about 1400℃. Since the melting point of aluminum is 500°C to 600°C, you can see its excellent heat resistance.

For this reason, it is an excellent metal panel that is also used for fireproof doors and other fireproof panels.

What are the design features of stainless steel panels?

Stainless steel panels and titanium panels are the only ones that can be exposed to the outdoors in their bare metal state.

Steel must be plated or painted. The same goes for aluminum. Copper and brass are metals that require even more care.

Therefore, it is possible to produce metal panels with infinite variations by polishing stainless steel panels with any design.

It is possible to create a space for each store, embody a designer’s image, or engrave the owner’s thoughts, local culture, and history on the surface of the metal panel.

Flexible expansion of stainless steel design panels

There are many designs to choose from. In addition, full orders and partial customization can be done freely.

Other. For more information about stainless steel on our site, click here!

Finally.

There are many variations of metal panels that contribute to the creation of distinctive spaces.

Among them, stainless steel design panels have a higher degree of freedom and can contribute to the creation of spaces and facades that have never been created before.